The sheets are hardened by spraying a stream of water on their surface and then tempered by annealing them in the temperature range of 500-700°C. After quenching, depending on the chemical composition of the steel and the cooling rate of the sheet, various structures are obtained. The purpose of tempering steel after hardening is to improve its plastic properties and obtain the required strength properties.

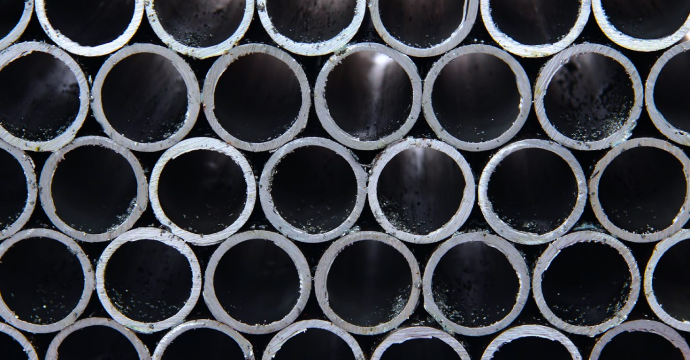

Heat-treated steels are used for the production of the following welded structures: crude oil storage tanks, cylindrical pressure tanks, tank cars for the transport of liquid gases, pipelines of pump power plants, bridges, high-rise building structures, drilling platform structures, chassis and jibs of mobile cranes and construction machines for earthworks.

Heat-treated steels are fine-grained low-alloy steels. By selecting the appropriate chemical composition, rolling conditions and heat treatment, it is possible to obtain steels with various levels of yield strength in the range from 450 to 1000 MPa.