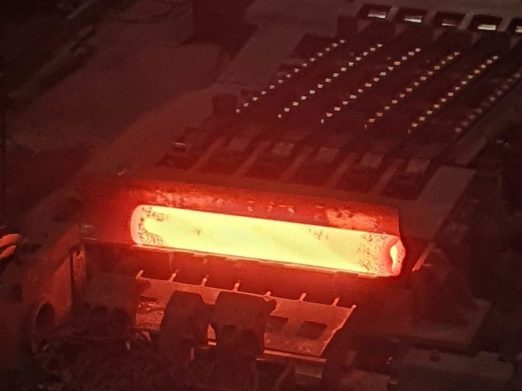

For seamless tube mills, the charge is in the form of ingots, slabs or billets. The first stage of the production process consists in dividing the charge, i.e. cutting it into appropriate lengths. The charge is then heated in a rotary hearth furnace. The main purpose of heating the steel charge in the rolling mill is to increase its susceptibility to plastic deformation. This has a significant impact not only on the course of the rolling process itself, but also on the degree of loads exerted on the devices involved in rolling.

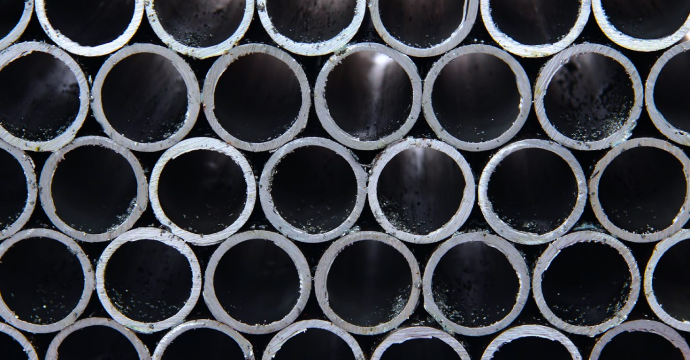

Production of pipes by hot rolling