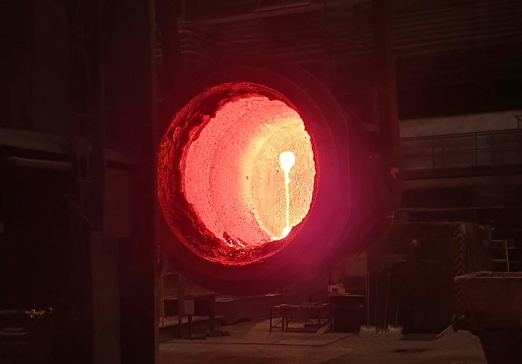

The first stage is smelting the steel in an EAF (Electric Arc Furnace). It is an electric furnace in which the charge (mainly contaminated steel scrap) is heated by an electric arc arising between the charged material and the electrodes. The arc reaches a temperature of several thousand degrees Celsius, which allows the charge to heat up to a temperature of about 1500 ° C and melt it without losing its electrochemical properties. Approx. a quarter of global steel production uses arc furnaces. This means a huge consumption of graphite electrodes, which significantly reduce the amount of energy needed to produce steel.